Insize 6888

PATENT PENDING

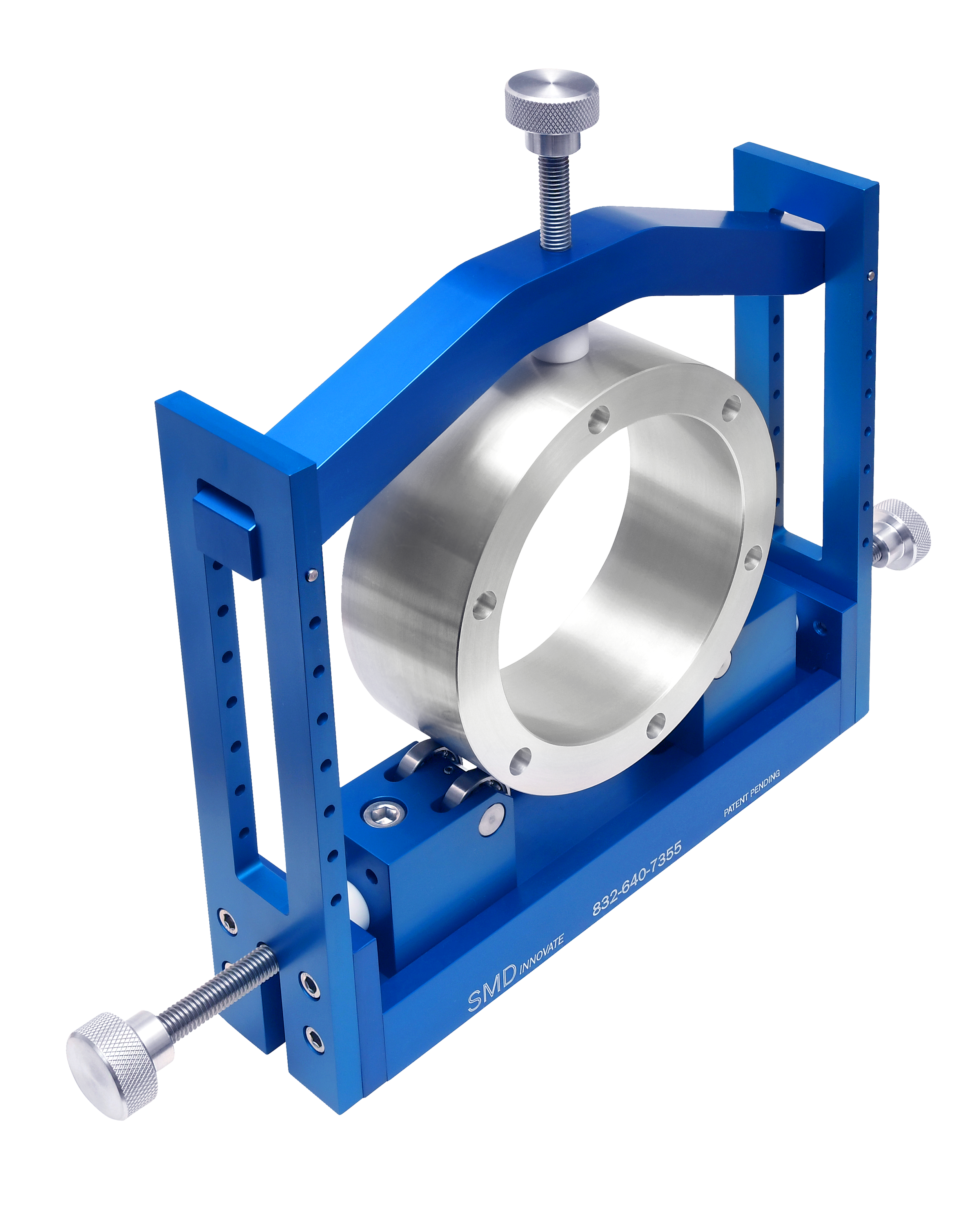

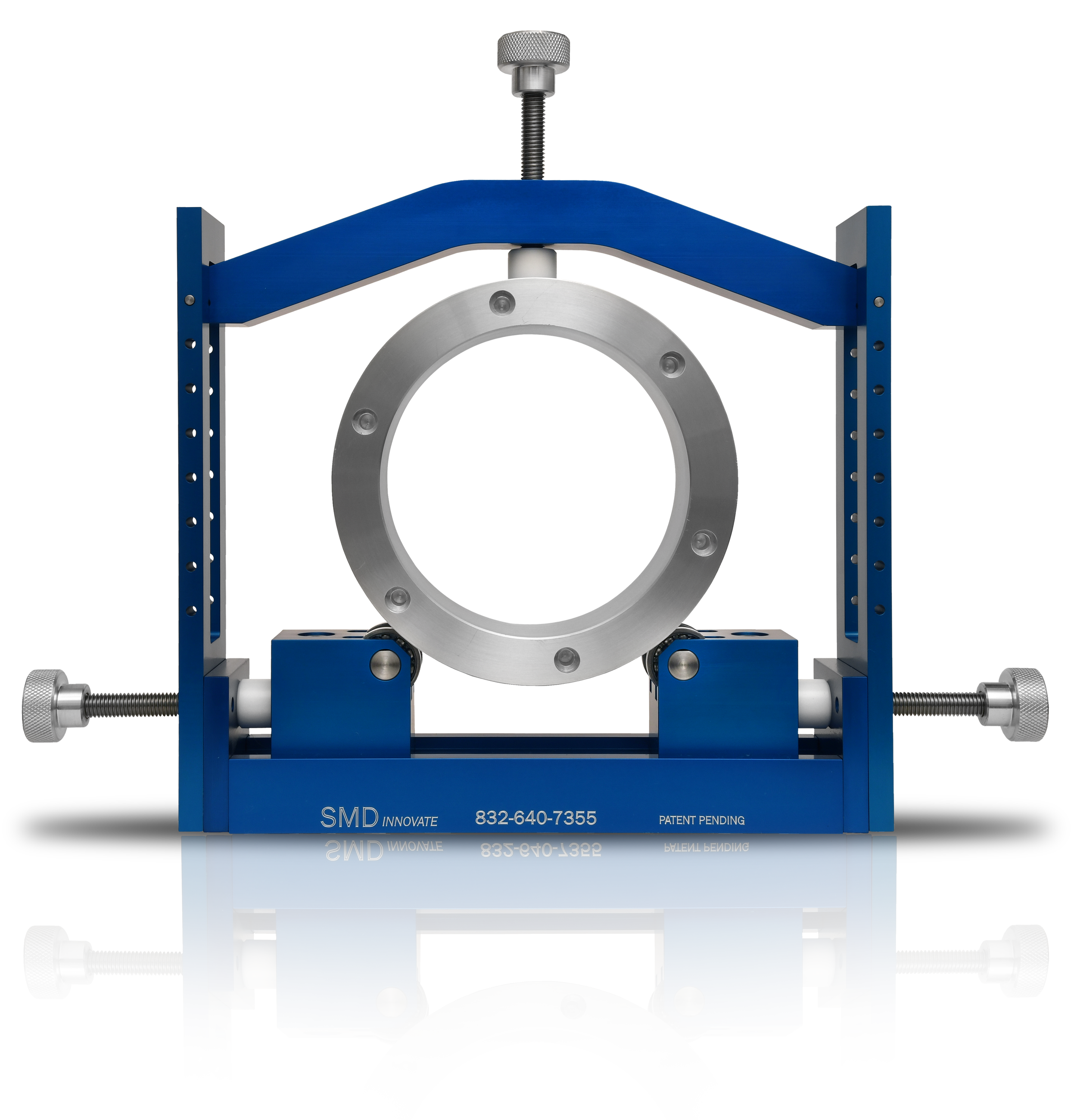

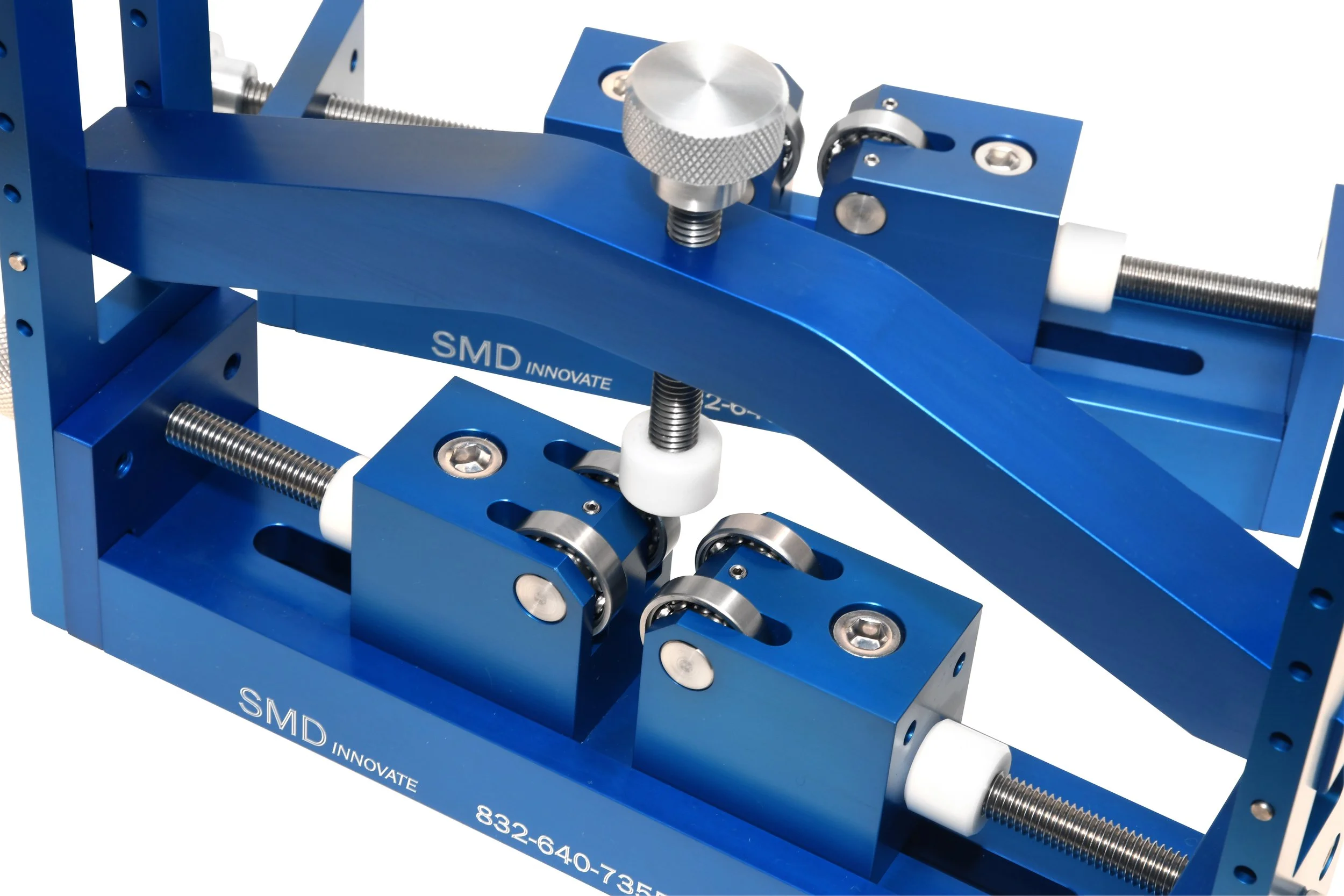

Adjustable Roller V-Block Set

(Top Clamp Sold Separately)

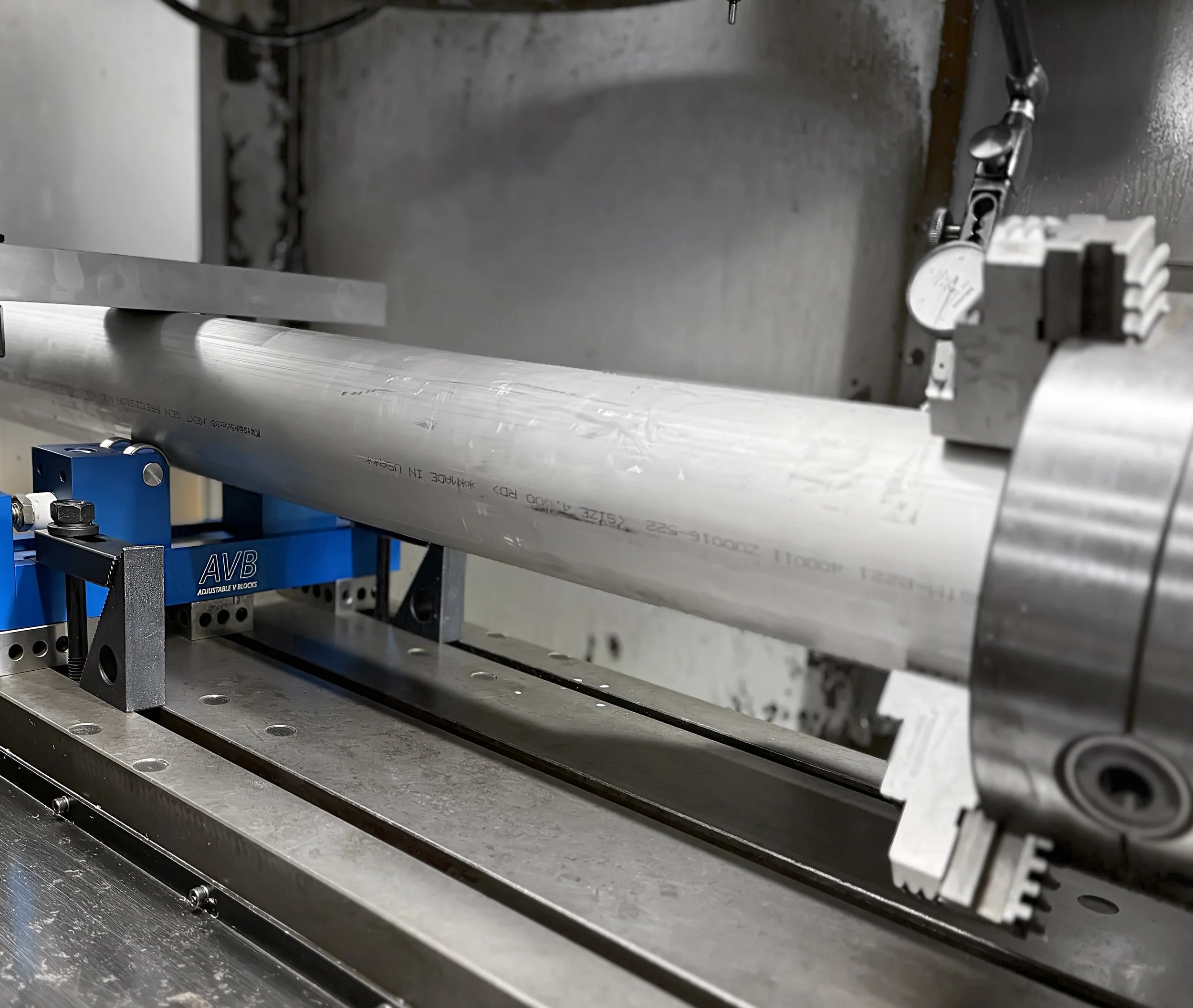

Inspect cylindrical lathe work for concentricity, straightness and T.I.R. (total indicator runout).

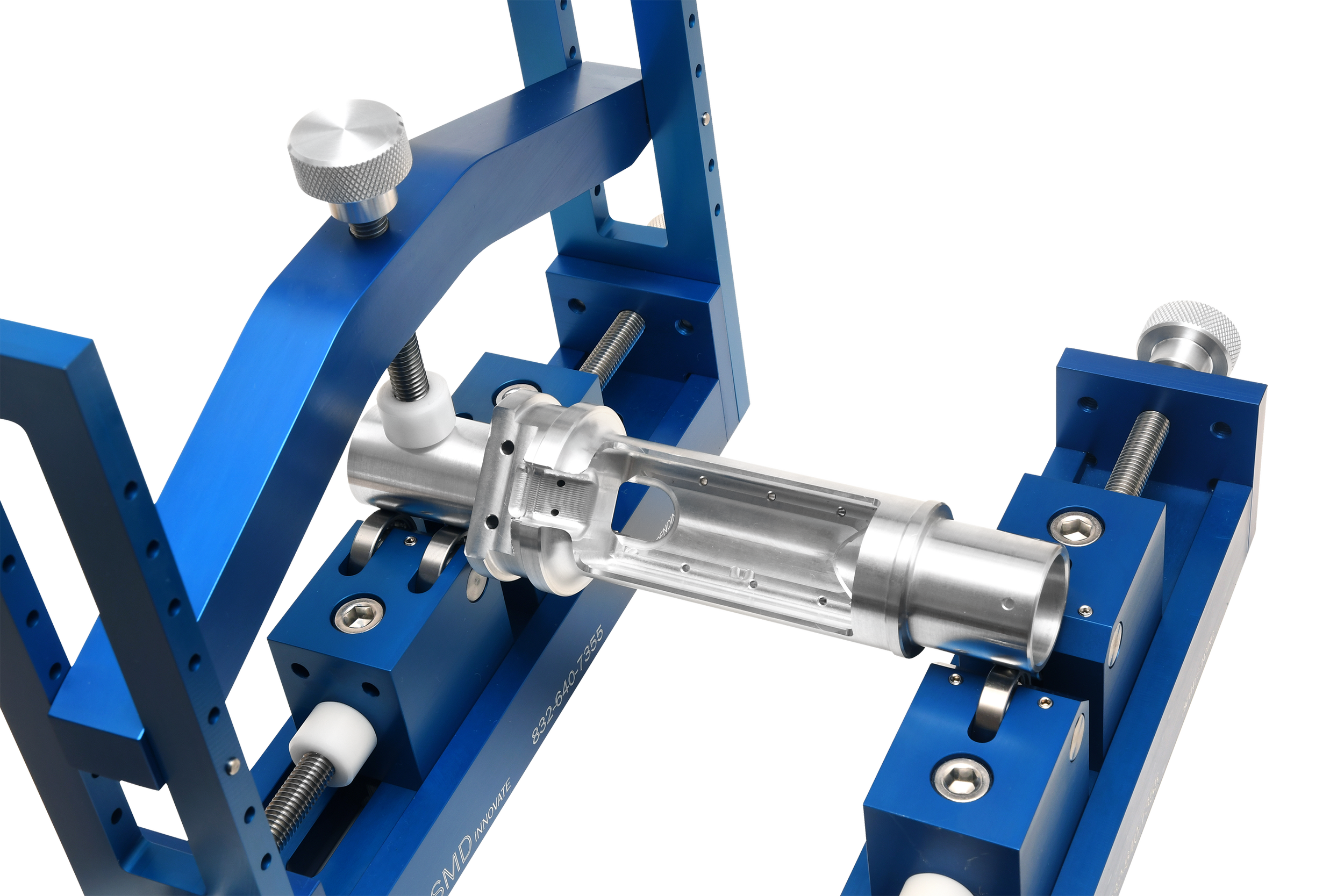

Great for orienting and locking diametrical and end horizontal work with our A.V.B. Orient and lock into position mill details and short parts with our Industry first "double locking bearing system" and finish protecting Delrin tipped top clamp.

Innovative Precision

Smith Machine Dynamics has been Houston’s trusted partner in precision machining since 2017, serving the Gulf Coast’s energy, petrochemical, and industrial sectors with unmatched quality, customer service and solution based product innovation.

Located in Northwest Houston, our state-of-the-art facility is equipped with advanced CNC machining capabilities, allowing us to meet the highest standards in precision manufacturing. We are committed to delivering excellence, supporting the region’s most demanding industrial needs with reliability, accuracy, and performance.

USED BY

FOLLOW US ON INSTAGRAM

On Mill as Steady Rest

“Finally checked my cylindrical work for T.I.R. with this and caught a 0.002 runout I would have missed! The AVB lets you inspect concentricity, straightness, and total indicator runout with pinpoint accuracy. Set up takes seconds and the readings are rock steady. I've caught runout issues as small as 0.001 that would have caused problems downstream.

Quality control just got easier with proper workholding that doesn't interfere with your measurements. Don't let runout slip by - grab the Smith Dynamics AVB system and catch every deviation.”

Contact Us

Interested in the AVB? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!